| Watermax is a reputed reverse osmosis plant provider in the country. Our industry professional’s best utilize the company resources for incorporating efficient water treatment mechanism for commercial buildings & industries. The range is designed as per the set industrial norms and clients’ specifications. |

| Our industrial R.O systems, also known as reverse osmosis systems remove bacteria and about 90 -95 % of the totally dissolved solids ( TDS) to provide tasty and safe drinking water right at your industry and Residential. |

| |

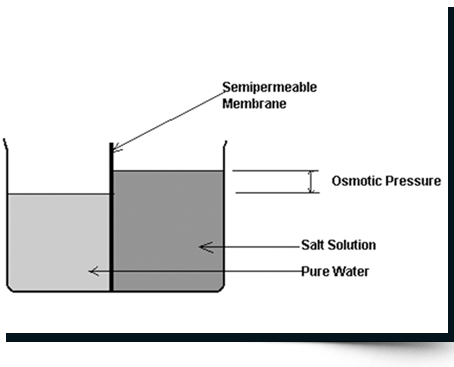

| WORKING PRINCIPLE : |

| |

| Reverse Osmosis is exactly opposite to Osmosis where the solvent molecules move from the region of higher concentration to a region of lower concentration with the aid of an external pressure which is equal and opposite to the Osmotic pressure. |

|

| The RO membrane has a pore diameter of 0.0001 micron (ie.,0.00000004 inches) which is smaller than bacteria ( mm to 1 mm) and virus (0.02 mm to 0.04 mm) thereby ensuring effective filtration (99.9%). Such fine pores ensure that up to 95% of the ionic impurities do not escape through the membrane. The turbulent flow of water over the membrane surface minimizes the accumulation of particulate matter on the membrane and facilitates continuous operation of the system. This membrane is made of thin, multi-layered high quality polyamide sheets. The design of the RO PLANT is primarily based on two factors . TDS content in the feed water and the recovery/reject ratio. In the separation process, purified water permeates the membrane and is collected separately, while the reject water containing concentrated dissolved and suspended solids is discharged to the drain. The passage of water also depends on factors like molecular size and diffusability co-efficients. The feed water flows continuously across the membrane and the rejected solids get into the back flow and is sent to the reject port. This process continues without clogging the membrane. |

|

|

| |

| Typical packaged RO system comprises of : |

| |

|

|

10 /05 Micron Cartridge Pre Filter |

|

|

Flow Switch |

|

|

Pressure Booster Pump |

|

|

Membrane Modules |

|

|

Reject Control Valves

|

|

|

Tubing And Fittings |

|

|

Permeate Flow Indicator |

|

|

Pressure Gauges |

|

|

|

|

|

|

| Optional Upgrade Packages Include : |

| |

|

|

Feed Pump |

|

|

Pre-Treatment Filter |

|

|

Chemical Dosing Systems |

|

|

Auto Flushing |

|

|

Micro PLC Based Controller

|

|

|

CIP System With Cartridge Pre Filter |

|

|

| |

| Special Features : |

| |

|

|

Product flow rate 0.2 m3 /Hr to 60 m3/h |

|

|

Fully and Semi Automatic |

|

|

Cabinet and Non – Cabinet Type System |

|

|

Maintains floor tiles, marbles |

|

|

Very compact and Skid Mounted

|

|

|

On skid Membrane Cleaning System |

|

|

Salt rejection ranges from 90 - 98% depending upon water quality |

|

|

Product recovery ranges from 50 - 80% based on feed water composition. |

|

|

Continuous Water Quality Monitoring through TDS Meter |

|

|

|

| |

| Advantages |

| |

|

|

Modular design - capacity can be increased to suit requirements. |

|

|

Fully assembled skid, tested prior to shipment, ease of installation and beneficial use. |

|

|

Non-corrosive low pressure piping - virtually maintenance free. |

|

|

Low on energy consumption. |

|

|

User friendly unit - does not require continuous monitoring. |

|

|

Easily handle the hard water. |

|

|

Removes unpleasant smell & odour |

|

|

| |

| APPLICATIONS : |

| |

|

|

Ultra pure water for electronic industries with combination of DM Plant |

|

|

Ultrapure water for pharmaceutical industries |

|

|

Provides Healthy & Hygene Drinking Water |

|

|

For Dialysis Application in Hopitals |

|

|

Process water for manufacturing plants |

|

|

Boiler feed water with Combination of Softener |

|

|

Beverage and food processing industry |

|

|

Bio-technology |

|

|

Mineral water |

|

|

|

|

|

| |